Carl SchwENGers GmbH

Engineering for the next generation

Our mission

We always have the next generation in mind. We want to preserve and improve our world for future generations through long-term, sustainable engineering of new, unconventional, innovative solutions with a long service life and optimal lifecycle properties.

Our standards

Reliability and individual orientation to our customers are the highest standards for us. We demand openness, honesty and maximum quality in our work processes from ourselves every day. Through this intrinsic standards, we ensure long-term, sustainable customer and employee relationships.

Our competencies

E/E engineering

- Requirement analysis and system design

- Component selection and SW engineering

- Integration and validation of technical systems

E/E engineering is the design, development and integration of electrical and electronic system components in technical applications in the automotive, aerospace, rail vehicle and industrial automation industries. This includes the selection and integration of sensors, actuators, control units, power electronics, communication interfaces and many other sub-components.

A particular challenge in E/E engineering is mastering the growing complexity. Electrical and electronic systems are becoming more and more extensive and powerful and require careful development of system architectures, efficient interface management and good system integration. The development process in E/E engineering includes several phases, starting with the requirement analysis, system design, component selection, circuit development, software programming, through to the integration and validation of the overall system. Talk to us and benefit from our experience and know-how in E/E engineering.

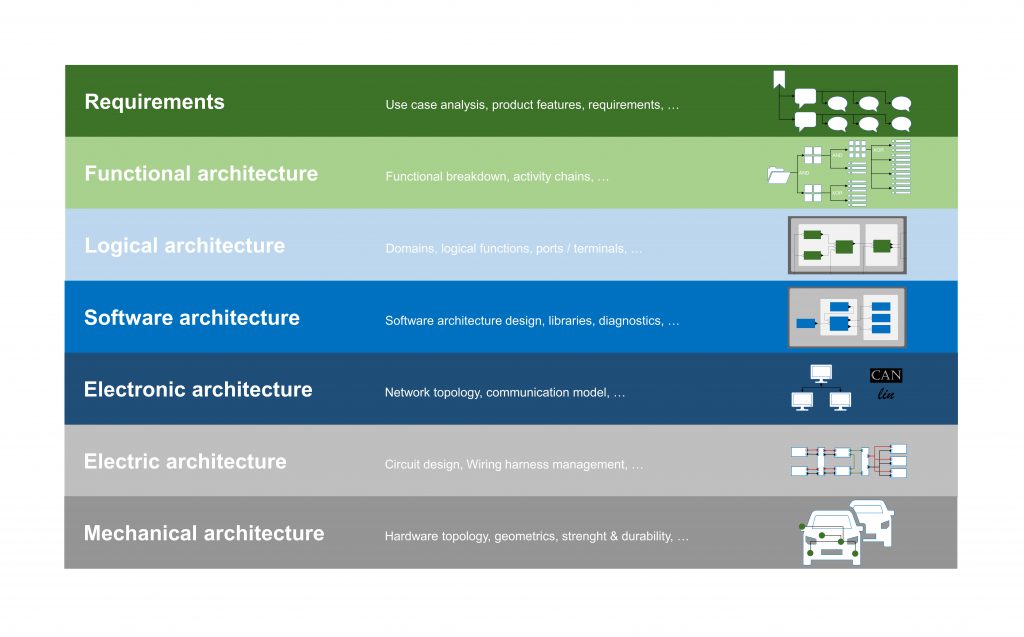

Functional analysis

- Breakdown of systems into activity chains

- Interface management and system integration

- Identification of re-usable system components

As part of the system architecture development, the functional analysis breaks down a technical system into activity chains with dedicated sub-system tasks. The activity chains describe the flow of information within the individual subsystems, the sum of all subsystem tasks meets the overall technical system requirements.

The functional decomposition creates a clear structure that allows for a simpler understanding of the interactions between the individual system components and their contribution to the overall functionality. The functional analysis is therefore an ideal tool for interface management and system integration. It enables even the most complex systems to be processed and supports engineers in identifying potential for improvement and / or to develop new technical solutions.

A precise functional breakdown also identifies individual system elements that can be reused in other system designs or projects. This off-cycle engineering saves time and money in the long term and enables faster development of new systems, and thus creates competitive advantages through a shorter time to market.

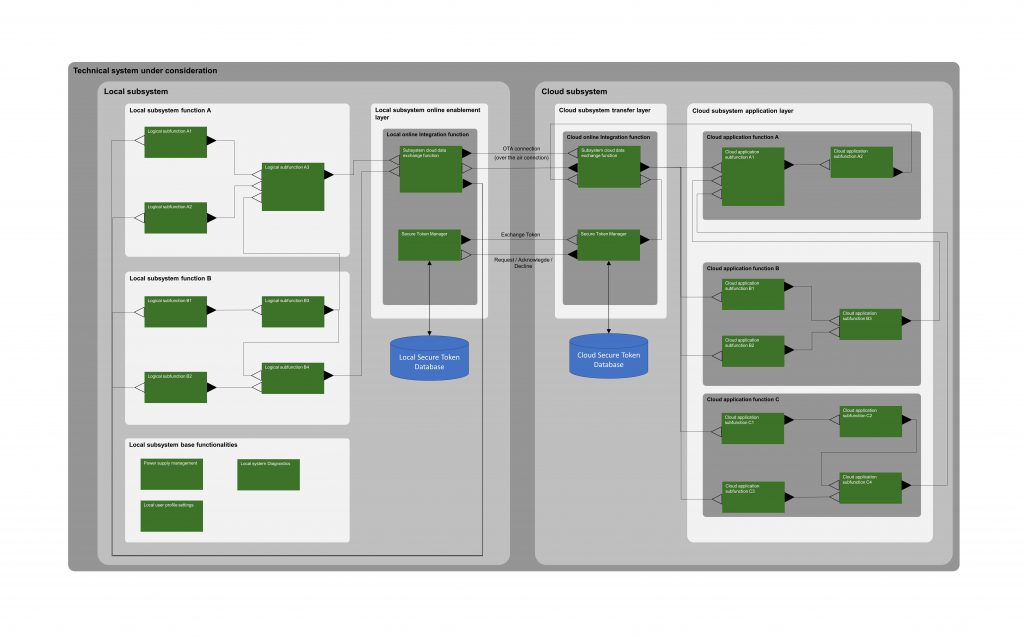

Model based system engineering

- Creation of digital twins

- Secure the "Single Point of Truth"

- Avoid the complexity trap

For the engineering of modern, highly complex E/E systems, the change in development processes from classic to model-based approaches is essential. With a product reference model, in the level of detail appropriate to the specific requirements, costs can be saved on a large scale in the long term, development times shortened and emissions reduced.

However, the development of the initial model itself involves a high upfront investment in terms of working hours, tool purchases and database engineering. With a partner at your side who has already accompanied the development of several complete and / or partial models for OEM, you benefit from the experience gained from these projects. In this way you can secure a long-term, manufacturer- and tool-independent “single point of truth” and avoid the “complexity trap”.

Together we determine the selection of suitable tools in the individual model layers, allocate information and make it available in your company for all authorized persons in an automated, search querry dependand simple and graphical presentation. We also support you in setting up the databases and the model themselves.

Reliability, Availability, Maintainability (RAM)

- Improving overall system reliability

- Effective, predictive maintenance planning

- Optimised maintainability & product lifecycle costs

At CSG we specialize on reliability, availability, and maintainability engineering of critical systems. In the demanding field of automotive and railway industry, where downtime can have significant consequences, our expertise in RAM engineering is invaluable for our customers.

We both design and / or analyse proposed solutions and products, ensuring proper RAM design and performance verification in the field. Our objective is to enhance system reliability through meticulous analysis. We conduct comprehensive risk assessments and evaluate failure modes to identify potential weaknesses. We are optimizing design cycles and facilitate the development of robust and reliable systems for our customers. Implementing effective planning, preventive maintenance protocols, and rapid response procedures further improve the availability of the final product, while developing solutions that streamline maintenance processes further enhance its maintainability and therefore cost efficiency. Finally our field performance verification processes ensure that systems meet the promised levels of availability and operational performance.

We are dedicated to ensuring the highest levels of reliability, availability, and maintainability for our customers, driving operational excellence and customer satisfaction.

Fuel supply systems

- Material and filter selection, pressure regulation

- Fuel flow dynamics and system integration

- Environmental friendly and easy to maintain

Designing robust and efficient fuel supply systems is a continuous careful consideration of various design aspects to ensure optimal performance and reliability.

The right choice of materials for constructing fuel supply components determines the systems chemical resistance, durability, and compatibility with different fuel types to ensure long-term integrity and to prevent corrosion or degradation. The Implementation of high-quality filters with the appropriate micron ratings remove contaminants, impurities, and particulate matter from the fuel, safeguarding the integrity of downstream components and optimizing engine performance. Accurate, advanced pressure control ensures consistent fuel delivery to the engine, enhancing combustion efficiency and minimizing the risk of engine damage.

In addition to material selection, filtration, and pressure regulation, we also consider factors such as fuel flow dynamics, system integration, and compliance with relevant industry standards.

Our engineering team works diligently to design fuel supply systems that not only meet performance specifications but also prioritize safety, environmental sustainability, and ease of maintenance. Partner with us for your fuel system engineering needs, and benefit from our experience, meticulous attention to detail, and commitment to delivering reliable, high-performance solutions.

Project engineering

- From customer requirement to commissioning

- Quality, time schedule, costs - stay in control

- Mixed team of project managers and engineers

We manage complex engineering projects with a strong focus on technical excellence. Our approach combines advanced project management methodologies to effectively coordinate various engineering disciplines, ensuring seamless collaboration and efficient communication. Our team of skilled engineers and project managers brings the experience to tackle challenges and deliver projects on time and within budget. With a keen eye for detail, we analyse project requirements, conduct feasibility studies, and develop comprehensive project plans. Through diligent risk management, we proactively identify potential obstacles and implement effective mitigation strategies to keep projects on track.

Our project engineering expertise extends to coordinating with suppliers, managing procurement processes, and overseeing equipment installation and commissioning. We maintain constant communication with stakeholders, providing regular updates and facilitating a smooth project lifecycle from inception to completion. We are dedicated to delivering successful engineering projects that meet your objectives and surpass expectations.

Product management

- Maximizing market success of technical products

- Advice throughout the complete product life cycle

- Positioning, market research, competitive analysis

Our product management services revolve around maximizing the value and market success of your engineering products. With a deep understanding of the technical landscape, we provide strategic guidance throughout the product lifecycle, from concept development to market launch.

We translate customer needs and market insights into actionable product requirements. Our product managers collaborate closely with engineering teams to define product specifications, ensure technical feasibility, and align product development with market demands. Throughout the product development processes, we facilitate efficient design iterations, prototype testing, and validation. Our emphasis on agile methodologies allows for iterative improvements and rapid adaptation, ensuring a competitive edge in the market.

Product positioning is optimized by market research, competitive analysis, and user feedback assessments. Throughout the product lifecycle, we maintain a strong focus on technical excellence, quality assurance, and regulatory compliance. Our rigorous testing and validation processes ensure that products meet the highest standards of performance, safety, and reliability.

Quality & process engineering

- Leveraging your optimization potential

- Manufacturing efficiency and reducing costs

- Process control, error & root cause analysis

Our quality and process engineering methodology begins with in-depth analysis and evaluation of existing processes. Through rigorous assessment, we identify areas for improvement, focusing on enhancing product quality, optimizing manufacturing efficiency, and reducing costs. By implementing lean manufacturing principles and advanced quality control techniques, we streamline operations and drive continuous improvement. Employing statistical process control, error-proofing techniques, and root cause analysis mitigates risks, minimizes defects, and enhances overall product quality.

The approach also includes comprehensive supplier quality management to ensure consistent performance and adherence to specifications. Proactive quality planning and design for manufacturability improves production efficiency, reduces lead times, and enhances customer satisfaction. Finally, we conduct audits and inspections to monitor compliance with industry standards and regulatory requirements.

Especially our software quality engineering approach is based on a strict verification process, but above all on detailed configuration management. This way, we ensure the traceability of artifacts and changes, as well as continuous fulfillment of all product requirements.

The quality & process engineering we implement ensure that our clients’ products meet the highest quality and safety standards throughout their lifecycle.

Our offer

Development service provider

As a development service provider, we are your extended workbench and accompany you in all process steps from design, development, integration to product lifecycle management and updates. Through our cooperation with partners, we enable a fast ramp-up in our projects.

Our special focus in this regard is on the formation of long-term customer relationships and sustainable employee loyalty.

Engineering office

In our engineering office, we offer technical expertise and the passion to penetrate complex technical issues. We are constantly evolving to be able to assess the market and the products of our clients. Our goal is to always find innovative, new and sustainable solutions.

Technology consulting

We offer you tailor-made solutions and comprehensive advice in selecting the correct tools & technologies to meet the customer requirements of tomorrow. Our experienced team will help you identify, implement and optimize technologies to achieve your business goals and gain additional competitive advantages.