Our core competencies

Our core competencies

As a development service provider, we offer you the full-service approach of an extended workbench. More details about our services can be found here.

Above all, we offer you a special service that goes beyond what can be expected in our core competencies. The roots from which our company has developed are in these disciplines. When working with CSG in these areas of competence, our employees will convince you with skills that you will not find, or will find only with difficulty, on the market elsewhere.

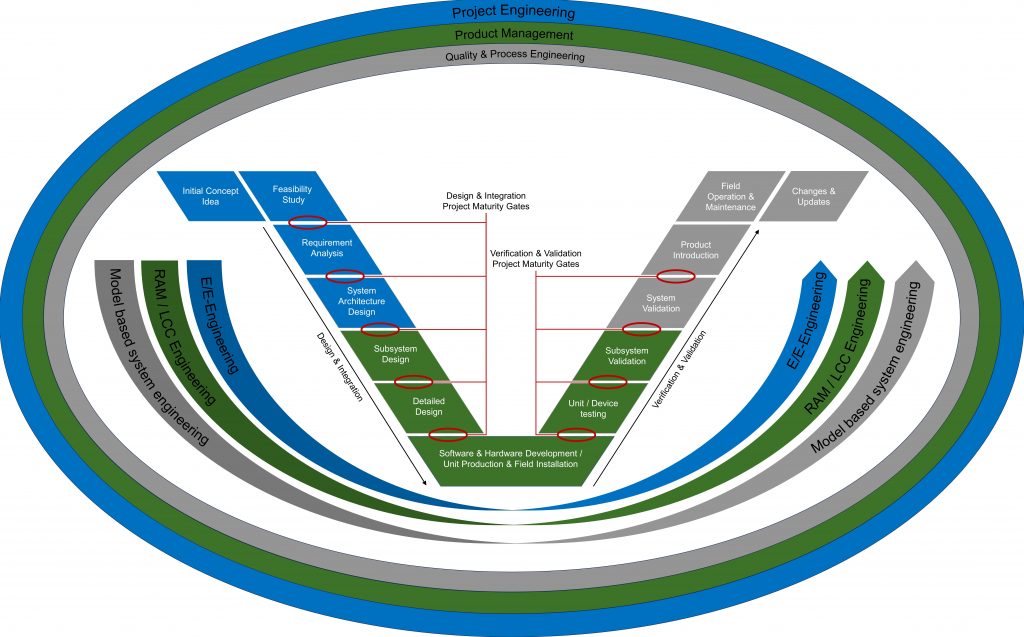

Developed from E/E engineering and the RAM/LCC disciplines in the rail vehicle industry, as well as model-based system engineering, in particular the functional analysis of subsystems and the design of fuel supply systems in the automotive sector, we now cover these disciplines across industries and use the resulting synergy and learning effects from our preliminary projects for our customers. Our engineers have not only made a name for themselves as senior project engineers, but have also exceed in the areas of product management and process engineering. We look forward to supporting you in the future.

E/E Engineering

E/E engineering is the design, development and integration of electrical and electronic system components in technical applications in the automotive, aerospace, rail vehicle and industrial automation industries. This includes the selection and integration of sensors, actuators, control units, power electronics, communication interfaces and many other sub-components.

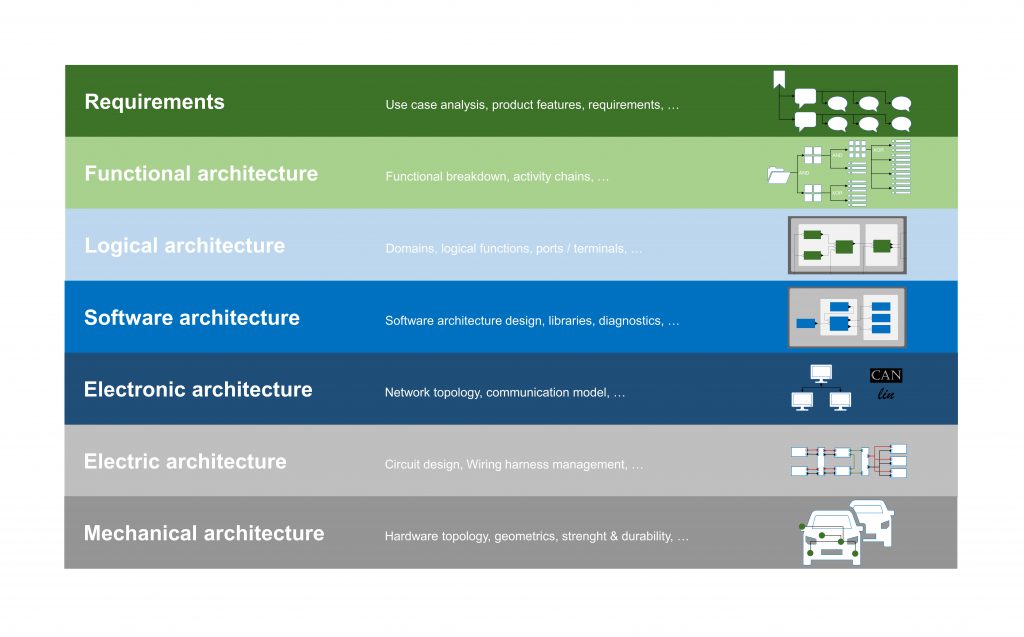

A particular challenge in E/E engineering is mastering the growing complexity. Electrical and electronic systems are becoming more and more extensive and powerful and require careful development of system architectures, efficient interface management and good system integration. The development process in E/E engineering includes several phases, starting with the requirement analysis, system design, component selection, circuit development, software programming, through to the integration and validation of the overall system. Talk to us and benefit from our experience and know-how in E/E engineering.

Modern E/E Engineering: Complex Interactions, Processes, and Challenges

In modern E/E development, engineers must manage complex interactions arising from the interfaces between electronics and electrics, adding software application behaviour as a tertiary challenge. The complex interactions between electronics and electrics in E/E systems arise due to their interdependence and the need for seamless integration. Electronics and software application behaviour directly influence the operation of electrical components, and vice versa. This intricate relationship poses challenges in various aspects of E/E engineering. Understanding the intricacies of these interactions is crucial for successful design and operation of E/E systems. Aspects of E/E engineering include requirements analysis, system design, component selection, software development, integration, and validation.

The modern design process is supported by a large variety of tools and databases offered by various suppliers. Often model-based, multi-author tool landscapes and open approaches with extensive import and export capabilities are needed to address the complexity of modern E/E systems.

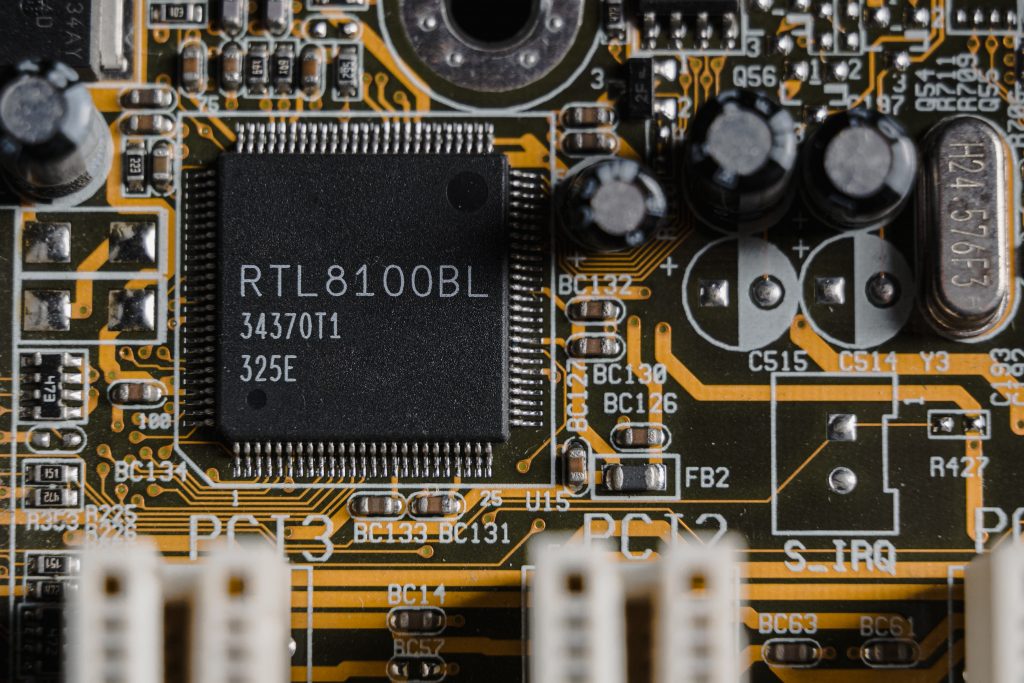

Electronics refers to the field of engineering that deals with the design, development, and application of electronic circuits and systems. It involves the study of electronic components, such as resistors, capacitors, and integrated circuits, and focuses on the behaviour and control of electric currents within these systems.

Electrics encompasses the generation, distribution, and utilization of electrical energy, including power transmission, wiring, and electrical devices.

Software application development in the context of E/E engineering refers to the process of designing, creating, and maintaining software programs that control and interact with electronic components and electrical systems. It involves activities such as requirements analysis, software design, coding, testing, and debugging. Software behaviour within E/E systems defines how the software interacts with hardware, processes data, communicates with other subsystems, and delivers the intended functionality. It encompasses factors such as real-time performance, reliability, safety, and adherence to industry standards and protocols. Effective software development ensures the seamless operation of the E/E system and enables the desired behaviour and functionality of the software applications.

1. Requirements Analysis: Requirements analysis involves identifying and documenting the functional and non-functional requirements of the E/E system. This process requires a deep understanding of the system’s intended functionality, safety, reliability, and performance. Challenges in requirements analysis include managing stakeholder expectations, balancing conflicting requirements, and ensuring compliance with industry standards and regulations.

2. System Design: System design entails defining the architecture and interfaces of the E/E system. It involves selecting appropriate hardware and software components, determining communication protocols, and designing the overall system structure. The complex interactions between electronics and electrics must be carefully considered to ensure compatibility, performance, and reliability.

3. Component Selection: Component selection involves choosing the right electronic and electrical components that meet the system’s requirements. This process requires evaluating factors such as functionality, performance, cost, availability, and lifecycle considerations. Careful consideration must be given to the compatibility and integration of selected components within the system.

4. Software Development: Software development plays a vital role in modern E/E systems, as software controls and interacts with electronic components. The challenges in software development include ensuring proper functionality, real-time performance, robustness, and safety. Additionally, software development for E/E systems often involves complex algorithms, signal processing, and control mechanisms.

5. Integration: Integration involves bringing together different hardware and software components of the E/E system to create a unified functioning system. The complex interactions between electronics and electrics become evident during the integration phase, requiring meticulous attention to detail to ensure seamless communication, data exchange, and interoperability between various subsystems.

6. Validation: Validation is a critical phase of E/E engineering, where the system is tested to ensure it meets the specified requirements. This process involves rigorous testing, verification, and validation of the system’s functionality, performance, safety, and compliance with standards. The complex interactions between electronics and electrics necessitate comprehensive testing strategies to ensure proper operation under various conditions.

Modern E/E systems involve intricate interactions between electronics and electrics and are characterized by their complexity, requiring advanced methodologies and tools for managing the engineering process. Understanding these interactions is crucial for successful design and operation of E/E systems. The processes of requirements analysis, system design, component selection, software development, integration, and validation all present their unique challenges.

OEM’s and tool manufacture alike emphasize the necessity of model-based, multi-author tool landscapes with extensive import and export features. These tools enable collaborative engineering efforts, provide a centralized repository for system models, and facilitate communication and consistency among multiple development teams. By utilizing such methods and tool landscapes, engineers can effectively manage the complexity of E/E systems, streamline the development process, and ensure efficient integration and validation. This approach is also described as model bases system engineering (MBSE). Additional information can be found here.

By addressing these challenges and employing effective engineering practices, engineers can develop robust and efficient E/E systems to meet the demands of the automotive industry.

Functional analysis

As part of the system architecture development, the functional analysis breaks down a technical system into activity chains with dedicated sub-system tasks. The activity chains describe the flow of information within the individual subsystems, the sum of all subsystem tasks meets the overall technical system requirements.

The functional decomposition creates a clear structure that allows for a simpler understanding of the interactions between the individual system components and their contribution to the overall functionality. The functional analysis is therefore an ideal tool for interface management and system integration. It enables even the most complex systems to be processed and supports engineers in identifying potential for improvement and / or to develop new technical solutions.

A precise functional breakdown also identifies individual system elements that can be reused in other system designs or projects. This off-cycle engineering saves time and money in the long term and enables faster development of new systems, and thus creates competitive advantages through a shorter time to market.

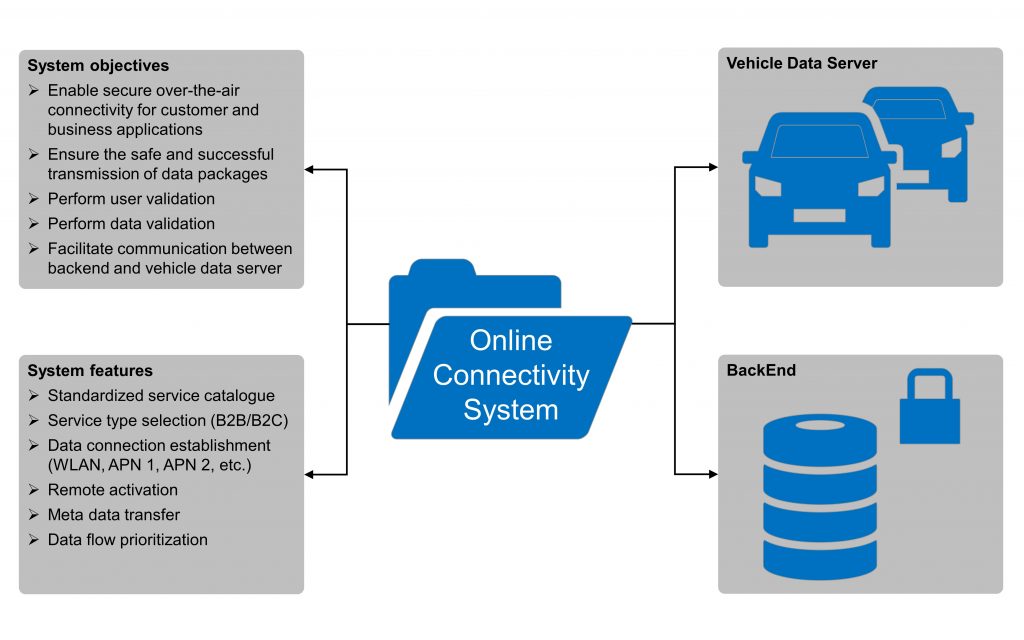

Functional Analysis on the example of an online connectivity system for passenger cars

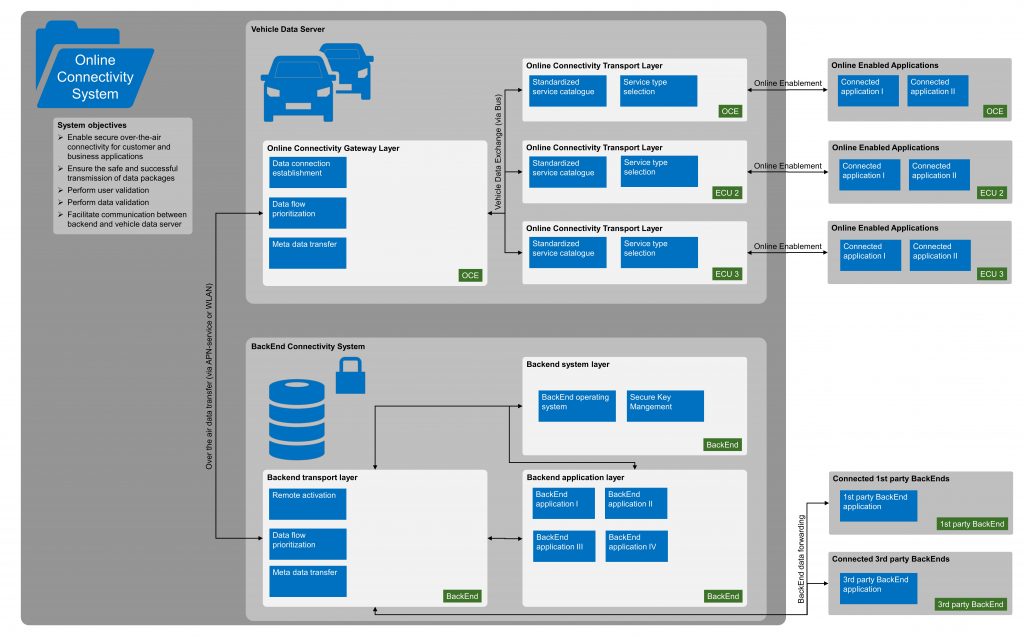

The purpose of the online connectivity system for passenger cars is to enable secure over-the-air connectivity for customer and business applications, ensuring the safe and successful transmission of data packages. The system performs user validation, data validation, and facilitates communication between the backend and the vehicle data server. Key functionalities include providing a standardized service catalogue with DNS-address targeting, data definition, service type selection (B2B or B2C), data connection establishment (WLAN, APN 1, APN 2, etc.), remote activation, meta data transfer, data flow prioritization based on code and requesting subsystem and other core features.

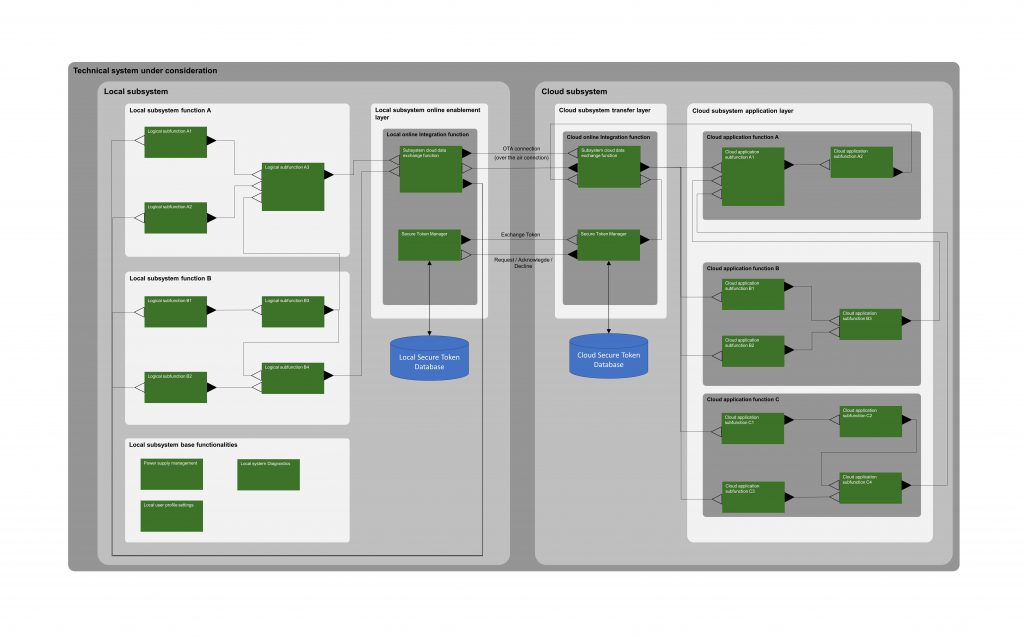

To fully grasp the system’s complexity, a stepwise functional analysis is essential. By breaking down the system into functional modular usable subsystems, the overall complexity becomes manageable, while the density of technical details described in each layer of the functional analysis increases.

The online connectivity system can be divided into two main subsystems: the backend server and the onboard vehicle platform, located in the vehicle’s electronic control units (ECUs). Inside the vehicle, a standardized gateway layer manages data flow between the vehicle and the backend. Multiple transport layers on various online-enabled ECUs ensure the use of standardized protocols and data exchange within the vehicle. Following the modular approach on the online connectivity ECU the gateway layer requires its own transport layer to facilitate online enablement of executed applications. Applications utilizing online data are executed outside the individual transport layers on the online-enabled ECUs.

Within the backend server, three layers can be identified: the system layer, the transport layer, and the application layer. The system layer provides basic operating system services for the backend, while the transport layer facilitates bi-directional data exchange to the vehicles and data forwarding to and from further 1st and 3rd party backends. The application layer runs individual backend application software packages for corresponding services on the vehicle’s ECUs (vehicle backend services).

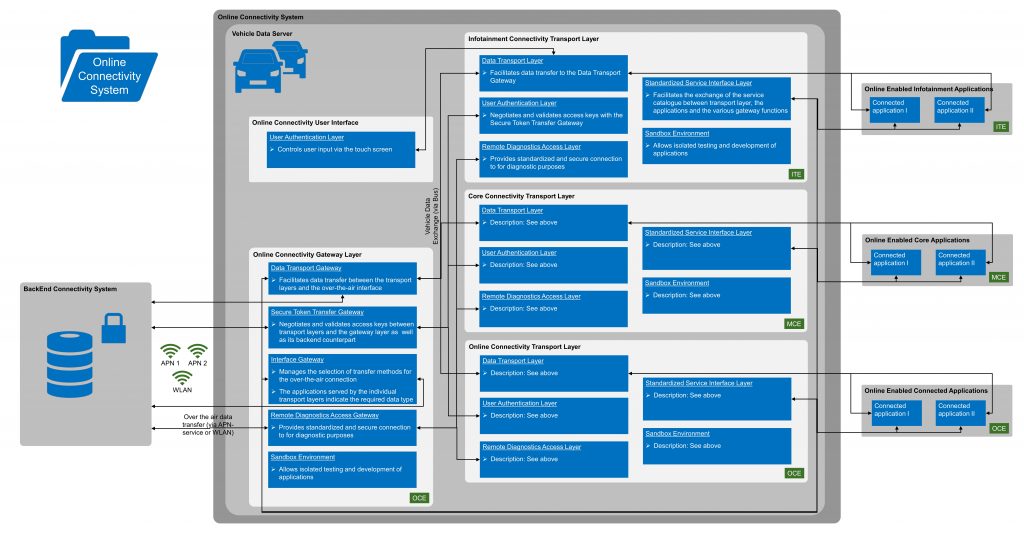

The gateway layer within the vehicle consists of multiple gateway sub-functions, each responsible for specific protocol routines. These sub-functions are:

- Data Transport Gateway: Facilitates data transfer in specified format between the transport layers and the over-the-air interface.

- Secure Token Transfer Gateway: Negotiates and validates access keys between the gateway layer and the backend counterpart, as well as between the gateway layer and the transport layers.

- Interface Gateway: Manages the selection of transfer methods for the over-the-air connection (e.g., APN 1 for B2B data, APN 2 for B2C data, WLAN as a preferred connection type if available). The applications served by the individual transport layers indicate their required data type.

- Remote Diagnostics Access Gateway: Provides a standardized and secure connection to the online-enabled ECUs solely for diagnostic purposes.

- Sandbox Environment: Allows isolated testing and development of applications.

The transport layers, located on the online connectivity ECU, infotainment ECU, and a sub-partition of the vehicle’s central multi-core ECU, consist of the following sub-functions:

- Data Transport Layer: Counterpart to the Data Transport Gateway.

- User Authentication Layer: Corresponds with the Secure Token Transfer Gateway.

- Standardized Service Interface Layer: Facilitates the exchange of the standardized service catalogue between the applications within the transport layer and the various gateway sub-functions.

- Remote diagnostics access layer: Counterpart to the remote diagnostics access gateway.

- Sandbox Environment: Allows isolated testing and development of applications.

The software for the online enablement system must be modular and compatible with multiple suppliers’ ECUs (up to 3 different suppliers – one for each ECU with a transport layer). Additionally, the infotainment ECU contains a specific software module as part of the online enablement system, which controls user input through the touch screen.

Both the gateway and transport layers can be further broken down into individual software classes linked to specific functions within the overall system. Thus, the functional analysis process can be extended beyond the example provided, allowing for deeper understanding and refinement of the system’s components.

By employing a systematic approach to functional analysis and modular design, engineers can manage the complexity of modern E/E systems while ensuring higher technical quality in each layer. This breakdown enables precise implementation, integration, and optimization of each subsystem, resulting in a more robust and efficient overall system solution.

Model based system engineering

For the engineering of modern, highly complex E/E systems, the change in development processes from classic to model-based approaches is essential. With a product reference model, in the level of detail appropriate to the specific requirements, costs can be saved on a large scale in the long term, development times shortened and emissions reduced.

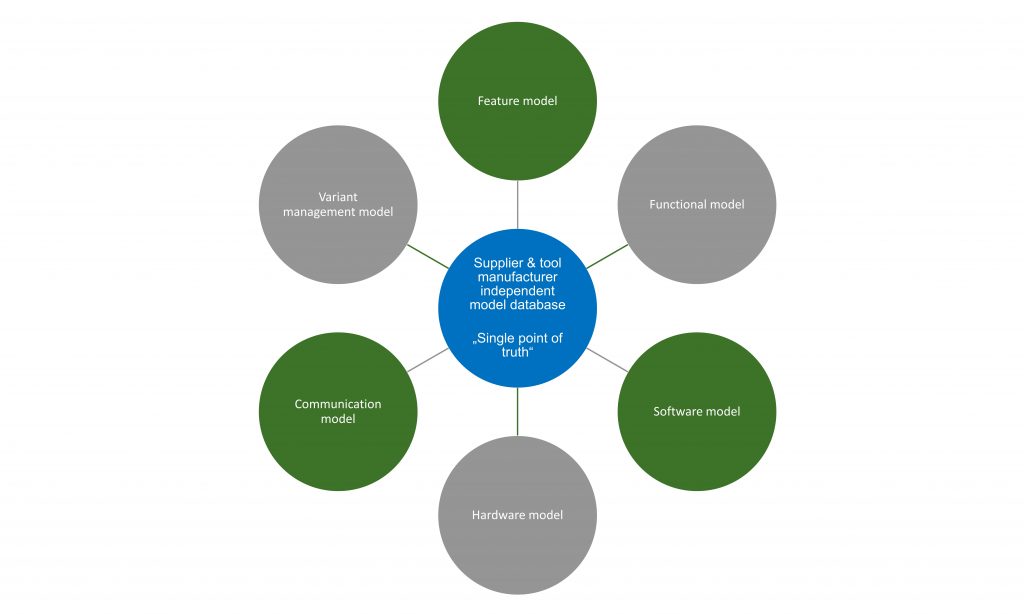

However, the development of the initial model itself involves a high upfront investment in terms of working hours, tool purchases and database engineering. With a partner at your side who has already accompanied the development of several complete and / or partial models for OEM, you benefit from the experience gained from these projects. In this way you can secure a long-term, manufacturer- and tool-independent “single point of truth” and avoid the “complexity trap”.

Together we determine the selection of suitable tools in the individual model layers, allocate information and make it available in your company for all authorized persons in an automated, search querry dependand simple and graphical presentation. We also support you in setting up the databases and the model themselves.

Leveraging Model-Based Systems Engineering for Creating Digital Twins in Automotive and Railway Industries

In the ever-evolving automotive and railway industries, the adoption of digital twins has emerged as a game-changer. These virtual replicas of physical products or systems hold immense potential for optimizing design, development, and operations. Examples for applications could be modern electric car platforms in the automotive industry or complete models of Electro Multiple Units (EMUs) in the railway industry. By following a systematic approach and leveraging the power of model-based system engineering (MBSE), companies can unlock new opportunities for innovation and efficiency gains. But simultaneously key facts must be respected during the digital twin model creation to ensure the success of MBSE introduction.

- Creating a full-scale digital twin model is a significant undertaking that demands considerable time and resources. Typically, for an OEM company the journey can span up to five years and require a multimillion-euro investment. To mitigate risks and ensure early returns, it is crucial to adopt a stepwise and modular approach, utilizing the already created aspects of the model while further aspects are under development. This approach allows companies to reap initial profits from the model and maintain momentum within the organization.

- In this process, it is vital to establish an independent database serving as the “single point of truth.” This database safeguards the company’s proprietary knowledge and ensures independence from third-party suppliers or tool manufacturers.

- Moreover, it is essential to avoid the complexity trap. While a digital twin model is a powerful tool supporting design, management, and operation, striving for a 100% precise model that replaces every aspect of the design phase can lead to excessive complexity, as the model needs to account for every potential deviation. It is thus more efficient to focus on creating a streamlined and simplified model with 80-90% accuracy. This approach, e.g., combined with rapid prototyping, allows for early verification of design implications, and provides a competitive advantage in the market.

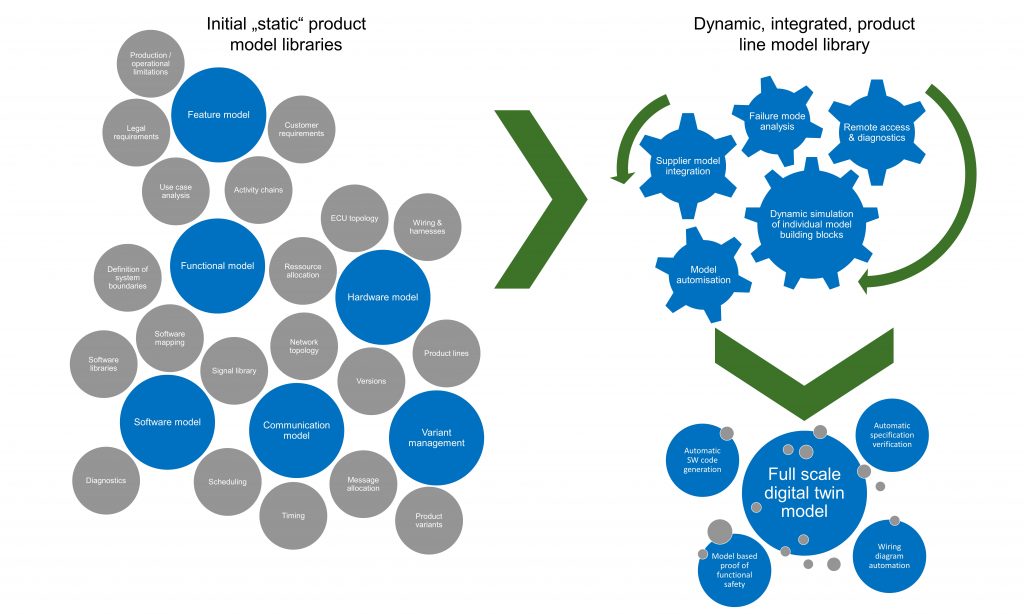

At the onset of the digital twin creation process, it is crucial to establish modular, comprehensive “static” product model libraries, consisting of the following key elements:

- Feature Model: The feature model encompasses an exhaustive analysis of use cases, capturing various scenarios that define the intended functionality and user interactions. Additionally, it incorporates customer requirements, addressing their specific needs and expectations. Legal requirements and production/operational limitations are also considered to ensure regulatory compliance and feasibility.

- Functional Model: The functional model serves as the foundation for the system’s behavior. It entails defining activity chains that outline the sequence and dependencies of operations. Clear system boundaries are established, delineating interfaces and interactions between subsystems. Software mapping ensures that software components align with functional requirements, while hardware allocation effectively assigns hardware resources.

- Software Model: The software model involves defining software libraries, diagnostics capabilities, and scheduling mechanisms. Software components and libraries are identified to support the system’s operations. Incorporating diagnostics allows for later real-time monitoring and troubleshooting, while scheduling mechanisms ensure the proper timing and sequencing of software tasks.

- Hardware Model: The hardware model contains the definition of the Electronic Control Unit (ECU) topology, which entails arranging and interconnecting ECUs. Additionally, it models the wiring and harnesses necessary to connect various hardware components. Managing different hardware versions and their compatibility within the system is a critical aspect of the hardware model.

- Communication Model: The communication model defines the network topology, specifying communication protocols and data exchange mechanisms. It also encompasses the creation of a signal library, facilitating efficient communication between different system elements. Timing requirements are established to ensure message transmission synchronization, and message allocation determines the appropriate distribution of messages.

- Variant Management Model: The variant management model allows for effective management of product lines and their associated variants. It provides the capability to define and configure different product variations to cater to diverse customer needs within the model landscape. In the model its direction is orthogonal to the other 5 modules.

To enhance the digital twin model’s capabilities, several dynamic features are incorporated onto the existing initial “Static” product model libraries.

- Dynamic Simulation of Individual Model Building Blocks: Through dynamic simulations, engineers can validate and verify the functionality of individual components and subsystems, ensuring they operate as intended within the overall system.

- Supplier Model Integration: Integrating models from different suppliers fosters compatibility and enables a comprehensive assessment of system-level performance, ensuring seamless integration across the product line.

- Failure Mode Analysis: Conducting failure mode analysis allows for the identification of potential failure modes and the incorporation of appropriate mitigation strategies, bolstering the digital twin model’s robustness and reliability.

- Remote Access & Diagnostics: Enabling remote access to the digital twin provides real-time monitoring, diagnostics, and maintenance capabilities, allowing for prompt response and efficient troubleshooting.

- Model Automation: Automating the model creation and updating processes reduces manual effort, enhances efficiency, and enables rapid adaptability to change and updates.

The culmination of the digital twin creation process leads to a comprehensive full-scale model with advanced capabilities:

- Model-Based Proof of Functional Safety: The digital twin model serves as a foundation for conducting model-based proof of functional safety, validating, and verifying that the system meets rigorous safety requirements and complies with industry standards and regulations.

- Automatic Specification Verification: Automated verification processes are employed to validate that system specifications align with the defined requirements, minimizing errors and discrepancies during the design phase.

- Automatic SW Code Generation: Leveraging the digital twin model, companies can streamline the software development process by automatically generating software code based on the model, reducing manual coding efforts, and ensuring consistency between the model and the implemented code.

- Automatic Wiring Diagram Generation: The digital twin model facilitates the automatic generation of wiring diagrams, providing accurate and up-to-date documentation for system wiring and harnessing, improving overall efficiency, and reducing human errors.

From a company’s perspective, leveraging model-based systems engineering (MBSE) in creating digital twins opens new frontiers in the automotive and railway industries. By adopting a systematic approach and integrating various model elements, companies can develop comprehensive digital twin models that drive innovation, optimize design processes, and enhance operational efficiency. Recognizing the time and resource requirements, it is crucial to work stepwise and modularly, utilizing already developed aspects while continuously improving the model. Establishing an independent database as the “single point of truth” safeguards intellectual property and fosters autonomy. By avoiding the complexity trap and focusing on a streamlined model, companies can harness the power of digital twins to gain a competitive edge and achieve their strategic goals.

Reliability, Availability, Maintainability (RAM)

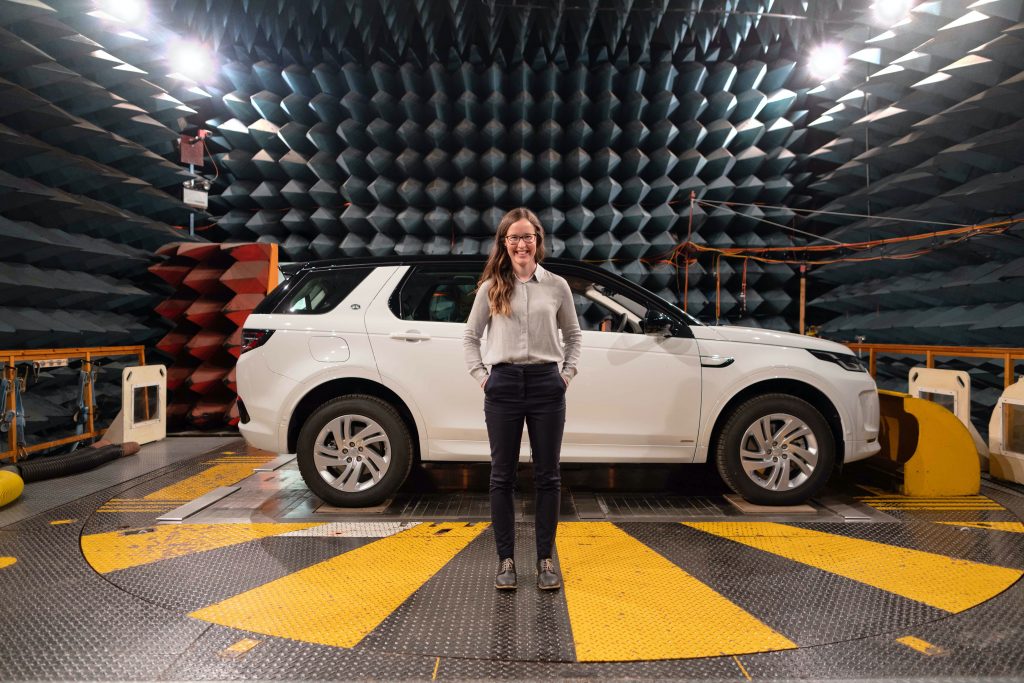

At CSG we specialize on reliability, availability, and maintainability engineering of critical systems. In the demanding field of automotive and railway industry, where downtime can have significant consequences, our expertise in RAM engineering is invaluable for our customers.

We both design and / or analyse proposed solutions and products, ensuring proper RAM design and performance verification in the field. Our objective is to enhance system reliability through meticulous analysis. We conduct comprehensive risk assessments and evaluate failure modes to identify potential weaknesses. We are optimizing design cycles and facilitate the development of robust and reliable systems for our customers. Implementing effective planning, preventive maintenance protocols, and rapid response procedures further improve the availability of the final product, while developing solutions that streamline maintenance processes further enhance its maintainability and therefore cost efficiency. Finally our field performance verification processes ensure that systems meet the promised levels of availability and operational performance.

We are dedicated to ensuring the highest levels of reliability, availability, and maintainability for our customers, driving operational excellence and customer satisfaction.

Reduction of product life cycle costs through RAM engineering in the rail vehicle industry

The rail vehicle industry is characterized by high demands on reliability, availability and maintainability. RAM (Reliability, Availability, Maintainability) engineering encompasses a holistic approach to optimizing vehicle performance, durability and maintainability, resulting in increased customer satisfaction and cost reduction. Especially in railway technology, the focus is on simultaneously securing the operation of vehicles with reduced downtimes and maintenance costs.

The manpower used for RAM engineering differs significantly between the individual markets and is ultimately driven above all by the contract design of the operator. Different customers, in different international markets, different operators such as the French State Railways (SNCF) and Germany’s Deutsche Bahn, have widely differing penalties and consequences for train failures, which in turn puts different pressures on manufacturers. While in France a lost journey that can be traced back to a defect in the responsibility of the OEM can cost up to several 100,000 euros in fines, in Germany only a few 1,000 euros are usually due for the same failure. Consequently, investments in RAM development resources and labor can vary widely depending on market needs and consequences.

Already during the design phase, an initial reliability and availability assessment is carried out based on compiled data from the suppliers’ components and subsystems. This assessment helps assess the overall system availability requirement, identify potential problem areas, and enable proactive measures to improve system reliability and availability.

Maintenance records are crucial both during the production process and after the product has been introduced to the customer. Rigorous inspections, adherence to maintenance schedules, and quality control procedures ensure products meet expected reliability and availability standards.

The focus on the maintainability of the individual subsystems in the design is another important aspect of RAM development. By considering easy access, modular design and standardized maintenance procedures, the time spent on maintenance activities can be minimized. This results in reduced downtime and improved operational efficiency.

Close collaboration between the product launch team, which is usually responsible for fixing the initial bugs after production, and the eventually deployed fleet monitoring team is crucial. This collaboration allows for seamless monitoring of vehicle performance, rapid identification of issues as they arise, and immediate corrective action.

Successful collaboration between OEMs and operators can further enhance maintenance and fleet monitoring efforts. By sharing expertise, data and best practices, OEMs can help operators optimize RAM performance to maximize customer satisfaction.

Effective tool-based fleet management (Enterprise Asset Management) enables operators to streamline maintenance schedules, manage spare parts inventory and streamline overall maintenance processes, thereby improving RAM performance.

The implementation of Fault Reporting, Analysis and Corrective Action Systems (FRACAS) enables real-time monitoring of fleet performance. By analyzing failure data, patterns and trends, potential risks and recurring problems can be identified, leading to proactive maintenance strategies. Error analysis methods such as root cause analysis, Ishikawa / Fishbone or 8D reports are indispensable tools in RAM engineering. These techniques make it easier to systematically investigate failures, identify root causes, and direct corrective actions to prevent future occurrences.

Modern rail vehicles allow access to diagnostic data via remote interfaces. The integration of remote diagnostic access and semi or fully automatic data analysis enables proactive planning of maintenance cycles. By identifying potential failures early, the required parts and resources can be prepared in advance, streamlining maintenance activities and minimizing unplanned downtime.

Integrating RAM engineering principles throughout the product lifecycle is critical to customer satisfaction and cost reduction in the railway industry. By conducting initial assessments, implementing design improvements, employing advanced monitoring techniques, and fostering collaboration, reliability, availability, and maintainability can be optimized, resulting in improved operational performance and reduced life cycle costs.

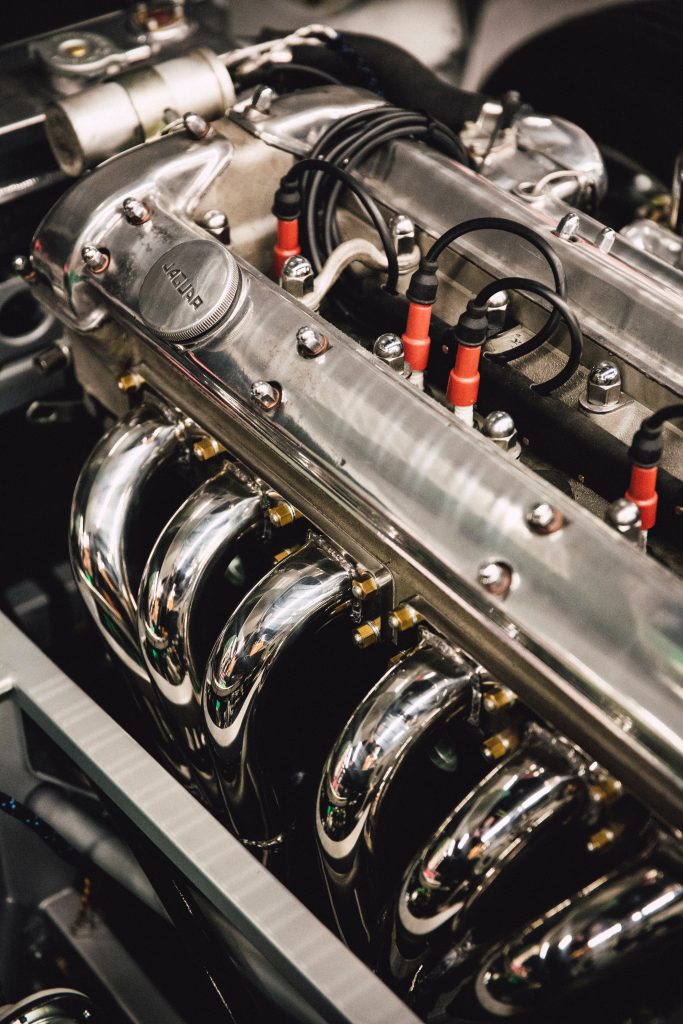

Fuel supply systems

Designing robust and efficient fuel supply systems is a continuous careful consideration of various design aspects to ensure optimal performance and reliability.

The right choice of materials for constructing fuel supply components determines the systems chemical resistance, durability, and compatibility with different fuel types to ensure long-term integrity and to prevent corrosion or degradation. The Implementation of high-quality filters with the appropriate micron ratings remove contaminants, impurities, and particulate matter from the fuel, safeguarding the integrity of downstream components and optimizing engine performance. Accurate, advanced pressure control ensures consistent fuel delivery to the engine, enhancing combustion efficiency and minimizing the risk of engine damage.

In addition to material selection, filtration, and pressure regulation, we also consider factors such as fuel flow dynamics, system integration, and compliance with relevant industry standards.

Our engineering team works diligently to design fuel supply systems that not only meet performance specifications but also prioritize safety, environmental sustainability, and ease of maintenance. Partner with us for your fuel system engineering needs, and benefit from our experience, meticulous attention to detail, and commitment to delivering reliable, high-performance solutions.

Fuel Delivery Systems in the Automotive Industry: Design, Integration and Performance

Sophisticated and optimized fuel supply systems ensure efficient, clean, controlled and reliable fuel supply for internal combustion engines. The design of fuel supply systems is a combination of filter design, material selection, system integration, pressure regulation, water separation, fuel flow dynamics and other relevant influencing factors. By understanding and optimizing these factors, automakers and suppliers can further improve the performance, durability and environmental impact of their vehicles.

Effective filtration ensures fuel quality is maintained and sensitive downstream engine components are protected. In the design, the selection of suitable filter media, the optimization of the pore size and the use of advanced filter technologies such as multi-layer filters and/or coalescence filters must be taken into account.

Proper selection of materials used for fuel delivery system components determines compatibility with different fuel types and ensures long-term durability. It is important to consider the corrosion resistance, chemical compatibility, mechanical strength and thermal stability of the materials used and to select the optimal configuration for different system components.

Efficient integration of the components of the fuel supply system optimizes the use of space in the vehicle. This includes component placement, fuel line routing, and integration with other vehicle systems.

Maintaining constant fuel pressure is necessary for optimal engine performance. The pressure ratio can be optimally adjusted through the use of fuel pressure regulators, fuel pumps and control algorithms. The use of fuel pulsation dampeners reduces pressure fluctuations and helps improve system stability. The use of variable flow rate pumps and/or adaptive pressure regulation algorithms can further increase the efficiency of the system.

Understanding the dynamics of fuel flow within the fuel delivery system is critical to achieving accurate fuel delivery and optimal injector performance. Influencing factors are the dimensioning of the fuel lines, the flow resistance, the pressure drop within the system and the influence of the fuel properties on the flow properties themselves.

Water contamination can adversely affect fuel system performance and engine operation. Strategies for effective water separation include the use of water separation filters, coalescing elements, and minimizing water ingress in the fuel system design.

The design and optimization of fuel supply systems is essential in the automotive industry for supplying internal combustion engines with clean and controlled fuel. By focusing on filter design, material selection, system integration, pressure regulation, water separation, fuel flow dynamics and environmental considerations, automakers can optimize their vehicles’ performance, durability and environmental impact.

Increasing regulatory requirements for the role of fuel-delivery systems in achieving these environmental goals, and industry initiatives aimed at reducing emissions, promoting fuel efficiency and promoting the use of alternative fuels, will transform the evolution of fuel-delivery systems . For the deployment of e-fuels, continuous advances in fuel delivery system technology will play a crucial role in shaping the future of automotive propulsion systems.

Project Engineering

We manage complex engineering projects with a strong focus on technical excellence. Our approach combines advanced project management methodologies to effectively coordinate various engineering disciplines, ensuring seamless collaboration and efficient communication. Our team of skilled engineers and project managers brings the experience to tackle challenges and deliver projects on time and within budget. With a keen eye for detail, we analyse project requirements, conduct feasibility studies, and develop comprehensive project plans. Through diligent risk management, we proactively identify potential obstacles and implement effective mitigation strategies to keep projects on track.

Our project engineering expertise extends to coordinating with suppliers, managing procurement processes, and overseeing equipment installation and commissioning. We maintain constant communication with stakeholders, providing regular updates and facilitating a smooth project lifecycle from inception to completion. We are dedicated to delivering successful engineering projects that meet your objectives and surpass expectations.

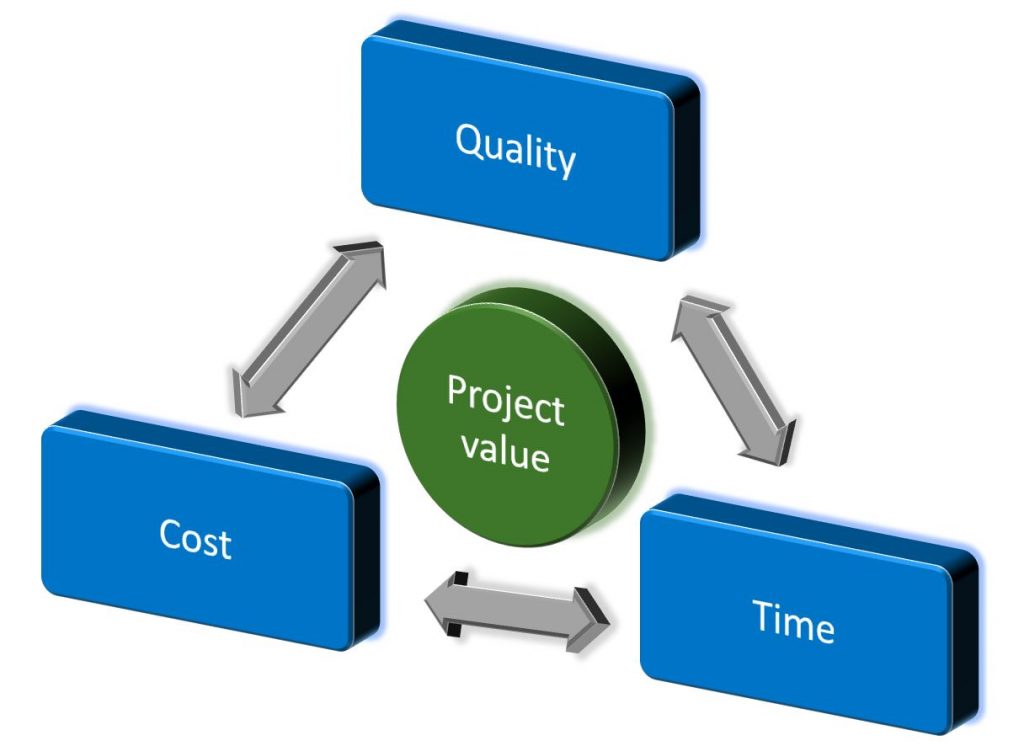

Project Engineering: Balancing time, cost and quality with team integration and technical leadership

Project engineering involves the coordination and management of resources to achieve project goals while meeting predefined time, cost, and quality goals. This includes technical risk management strategies, stakeholder engagement approaches, change control procedures, communication and reporting mechanisms, and lessons learned practices. In addition, team building approaches, a suitable vertical supplier and customer integration and the role of the technical manager in achieving the project goals play a major role. Project engineers make an active contribution to achieving these project goals in the various planning, integration and verification processes of a project.

Effective project planning requires the implementation of robust time, cost and quality control techniques. Tools such as project planning, resource allocation, risk management, progress monitoring, cost estimation, quality assurance and performance measurement (KPI) are used for this. Applying these methods appropriately for each project is a fundamental building block for projects to be delivered on time and within budget, and to meet or exceed quality expectations.

The success of project engineering always depends on the composition and dynamics of the project team. Examples of different approaches to team setup include the formation of cross-functional teams, matrix organizations and virtual teams. The selection of the team approach must align with the project task, as each approach offers unique advantages in terms of communication, collaboration and expertise matching, thus enabling effective project delivery.

Integrating suppliers and customers into the project development process can bring significant benefits. By directly involving important stakeholders in the project team, potential bottlenecks can be alleviated and project results can be optimized. Examples of possible benefits of supplier and customer integration are e.g. B. Shorter communication loops, greater engagement and better understanding of project requirements. Even when delays and errors occur, increased integration usually leads to solution-oriented approaches and avoids delays caused by finger pointing and/or the need for further legal safeguards.

The Technical Lead plays a crucial role in project development and acts as a balance to the project management team. From bringing in his/her technical expertise, coordinating design activities, resolving technical issues and ensuring project specifications are met, to making hard, fast engineering decisions, in many cases it is the personality of the Project Lead Engineer who/ who ensures the success of the project with his actions. The presence of the technical director ensures a full focus on technical aspects, while project management can focus on procurement, finance, marketing and other non-technical aspects.

Product management

Our product management services revolve around maximizing the value and market success of your engineering products. With a deep understanding of the technical landscape, we provide strategic guidance throughout the product lifecycle, from concept development to market launch.

We translate customer needs and market insights into actionable product requirements. Our product managers collaborate closely with engineering teams to define product specifications, ensure technical feasibility, and align product development with market demands. Throughout the product development processes, we facilitate efficient design iterations, prototype testing, and validation. Our emphasis on agile methodologies allows for iterative improvements and rapid adaptation, ensuring a competitive edge in the market.

Product positioning is optimized by market research, competitive analysis, and user feedback assessments. Throughout the product lifecycle, we maintain a strong focus on technical excellence, quality assurance, and regulatory compliance. Our rigorous testing and validation processes ensure that products meet the highest standards of performance, safety, and reliability.

Product management for driver assistance systems in the automotive industry

Product management plays a pivotal role in the successful development, lifecycle management and market penetration of driver assistance systems in the automotive industry. It involves the strategic planning, development, and continuous improvement of these systems to meet customer needs, industry regulations, and market demands.

Effective product management ensures the successful delivery of driver assistance systems that enhance vehicle safety, convenience, and user experience. It ensures that driver assistance systems are not only technically robust but also aligned with market demands and customer preferences. This requires a systematic and holistic approach to product development, incorporating defined steps and methods to achieve optimal results.

Implementing product management for driver assistance systems typically involves several key steps. Firstly, market research and analysis are conducted to understand customer requirements, industry trends, and competitive landscape. This research helps identify opportunities and define the target market for the driver assistance system. Secondly, product planning and definition take place, where the system’s features, functionalities, and performance metrics are defined. This includes setting specific goals, such as improved collision avoidance or advanced parking assistance. Additionally, a product roadmap is created to outline the development timeline and milestones.

A crucial step in the specific product management for driver assistance systems is the careful selection of detection methods. This includes assessing the suitability of various technologies such as radar, lidar, cameras, and other sensors. By combining these detection methods, a superimposed position of the vehicle in reference to its surroundings can be created, enabling accurate perception and decision-making algorithms. The choice of detection methods is based on factors such as performance, reliability, cost-effectiveness, and regulatory compliance.

Another key aspect of product management in general is the creation of a product roadmap. This roadmap outlines the development timeline and sets specific milestones for the driver assistance system. The development process typically begins with the conceptualization and feasibility assessment stage, followed by prototyping and validation. Milestones may include the completion of functional prototypes, successful testing and validation under various conditions, and regulatory certification. The roadmap provides a clear vision for the product’s development, aligns stakeholders, and enables effective resource allocation.

Product managers for driver assistance systems employ various methods to ensure market success and added value. Market analysis and customer research are conducted to understand evolving customer needs, identify market trends, and uncover potential gaps or opportunities. This information helps shape the product’s features, functionality, and user experience, ultimately driving customer satisfaction and market adoption.

In addition, product managers utilize business strategies such as market segmentation and targeting. By identifying specific customer segments that can benefit most from the driver assistance system, targeted marketing efforts can be employed to capture these segments effectively. This approach helps optimize the product’s value proposition and tailors marketing messages to resonate with the intended audience.

To ensure proper realisation a crucial method is user research and usability testing. This involves gathering feedback from potential end-users to understand their needs, preferences, and pain points. Usability testing allows for iterative refinement of the system’s user interface and interaction design, ensuring it is intuitive, easy to use, and meets the driver’s expectations.

Another important method is feature-prioritization and backlog management. By using techniques such as the MoSCoW method (Must-haves, Should-haves, Could-haves, Won’t-haves), product managers can prioritize the development of critical features while balancing resource constraints. This method ensures that the most essential functionalities are implemented first, providing immediate value to customers. Furthermore, iterative development processes, such as Agile methodologies like Scrum, are commonly adopted to enable flexibility, rapid prototyping, and incremental improvements throughout the product lifecycle.

The business benefits of effective product management are manifold. By aligning product development with market demands, product managers can secure a competitive advantage for their businesses and achieve sustainable market share. Furthermore, through continuous market monitoring and product improvements, they can adapt the product to changing customer needs, stay ahead of competitors, and maintain the established market position. Ultimately, successful product management ensures that driver assistance systems not only meet technical requirements but also deliver value to both customers and the system developers.

Implementing robust product management practices for driver assistance systems brings several advantages. It allows for a structured approach to product development, ensuring that customer requirements are met, and market demands are addressed. By incorporating user research and usability testing, product managers can optimize the system’s design and functionality, resulting in a better user experience. Additionally, feature prioritization methods help focus development efforts on the most impactful features, increasing customer satisfaction. Agile methodologies facilitate faster time-to-market, adaptability to changing requirements, and effective collaboration among cross-functional teams.

However, product management also comes with challenges. Balancing conflicting requirements and priorities can be complex, especially when dealing with diverse stakeholders and technical constraints. Managing expectations and ensuring alignment between different teams involved in the development process is crucial for successful product management. Moreover, the automotive industry is subject to stringent safety regulations, which can introduce additional complexities and requirements in the development and validation of driver assistance systems.

In conclusion, effective product management for driver assistance systems in the automotive industry is essential for delivering safe, reliable, and user-centric solutions with sustainable added business value. By following the steps outlined above and utilizing methods such as user research, feature prioritization, and agile development, companies can effectively drive successful product development, meet customer expectations, and stay competitive in the market.

Quality & process engineering

Our quality and process engineering methodology begins with in-depth analysis and evaluation of existing processes. Through rigorous assessment, we identify areas for improvement, focusing on enhancing product quality, optimizing manufacturing efficiency, and reducing costs. By implementing lean manufacturing principles and advanced quality control techniques, we streamline operations and drive continuous improvement. Employing statistical process control, error-proofing techniques, and root cause analysis mitigates risks, minimizes defects, and enhances overall product quality.

The approach also includes comprehensive supplier quality management to ensure consistent performance and adherence to specifications. Proactive quality planning and design for manufacturability improves production efficiency, reduces lead times, and enhances customer satisfaction. Finally, we conduct audits and inspections to monitor compliance with industry standards and regulatory requirements.

Especially our software quality engineering approach is based on a strict verification process, but above all on detailed configuration management. This way, we ensure the traceability of artifacts and changes, as well as continuous fulfillment of all product requirements.

The quality & process engineering we implement ensure that our clients’ products meet the highest quality and safety standards throughout their lifecycle.

Software quality engineering and configuration traceability

Software quality engineering plays a vital role in the development of software for automotive and railway applications, ensuring that the software meets stringent standards and requirements set by both customers and the state authorities, such as the EBA (Eisenbahn-Bundesamt) in Germany. These standardized quality and process requirements, along with other motivations like safety, reliability, and customer satisfaction, drive the need for robust software quality assurance systems. Software quality engineering involves a systematic and disciplined approach to verify and validate software throughout its development lifecycle.

Effective software quality engineering recognizes the significance of configuration management and version traceability. By implementing comprehensive configuration management processes, including version control and variant management, software development teams can effectively manage different software configurations tailored to specific customer needs or system requirements. This allows for efficient control of different software versions and variants, facilitating streamlined development, easier maintenance, and improved traceability. Version traceability ensures that the development team can track and understand the evolution of the software, including the specific versions and components used in a particular release or deployment. This traceability contributes to better change management, impact analysis, and compliance with industry standards.

The verification process in software quality engineering involves several key activities. Firstly, quality objectives are established and critical quality attributes, such as reliability, maintainability, and safety are identified. These objectives and attributes define the specific criteria that the software must meet to ensure compliance with regulatory standards and customer requirements. These objectives serve as benchmarks against which the software’s performance and functionality will be measured. Functional testing is then conducted to validate that the software functions as intended and meets the specified functional requirements. This involves testing individual components, modules, and the integrated system to ensure correct behaviour.

In addition to functional testing, other types of testing are performed to ensure various quality attributes. Performance testing is conducted to evaluate the software’s performance under different load conditions, assessing factors such as response time, throughput, and resource utilization. Security testing focuses on identifying vulnerabilities and ensuring that the software is resistant to unauthorized access, data breaches, and other security threats. Usability testing is carried out to assess the software’s user-friendliness, ensuring that it meets the needs of end-users and provides an intuitive and efficient user experience.

To meet the highly standardized quality and process requirements in the automotive and railway industry, the implementation of detailed quality assurance systems is essential. Quality plans are developed to define the specific activities, processes, and techniques that will be employed to ensure software quality. These plans outline the testing strategies, defect management procedures, and quality control measures to be followed during development. Documentation standards are established to ensure proper documentation of requirements, design specifications, test cases, and other artifacts, facilitating transparency and traceability throughout the development process.

Adherence to coding guidelines is critical in maintaining software quality. These guidelines define coding conventions, best practices, and design principles that developers must follow. They ensure consistency, readability, and maintainability of the codebase. By adhering to coding guidelines, the likelihood of introducing errors and bugs is minimized, improving the overall quality of the software.

Configuration management is of utmost importance in the automotive and railway industry. It ensures variant and version management, allowing for efficient management of different software configurations tailored to specific customer needs or system requirements. Configuration management also provides traceability, enabling the tracking of changes made to the software throughout its lifecycle. It ensures that the development team can identify and understand the specific versions, configurations, and components used in a particular release or deployment, facilitating easier debugging, troubleshooting, and maintenance activities.

Implementing detailed software quality assurance systems brings several advantages. Firstly, it helps mitigate risks associated with safety-critical systems, reducing the likelihood of accidents or failures. Secondly, it ensures compliance with industry regulations, avoiding potential penalties or legal consequences. Thirdly, it enhances customer satisfaction by delivering reliable and high-quality software solutions. Additionally, implementing these systems improves traceability, documentation, and transparency throughout the development process, making it easier to identify and rectify any issues that arise.

Traceability is a key benefit of implementing software quality engineering in the railway industry. Through proper documentation, version control, and configuration management, traceability allows for the tracking and mapping of requirements, design decisions, and testing activities throughout the software development process. This facilitates effective change management, impact analysis, and regulatory compliance. Traceability ensures transparency and accountability, enabling stakeholders to understand the evolution of the software and the rationale behind design choices.

CSG, as a provider of quality and process engineering services, offers tailored solutions to automotive and railway industry companies seeking to optimize their software development processes. With our expertise in implementing quality assurance systems, adherence to standardized quality and process requirements, and in-depth knowledge of configuration management, we can help your company achieve the highest levels of software quality, safety, and reliability. By leveraging our experiences and best practices, you can enhance your competitive edge, reduce risks, and deliver robust software solutions that meet the stringent demands of your industry sector.